Packaging Perfected: Your Guide to Mailer and Shipping Boxes

Date: 24-11-2025 | Read Time: 10 Mins

The first level of interaction with your product is the mailer and shipping boxes. They serve as the initial physical impression of your business to manage shipping expenses, and safeguard products throughout the journey. Empress Packaging gives the rightly designed mailer or shipping boxes will reduce the freight costs, decrease damage claims, and also generate repeat business for US retailers, subscription services, online-first businesses, and companies that target consumer directly brands through providing a memorable opening experience. The design, specification, along with the sourcing of mailer and custom shipping boxes that balance cost, sustainability, protection, and also brand impact are all tackled in this article.

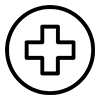

Mailers versus Shipping Boxes: Know the Difference

The primary uses of custom mailer boxes and shipment boxes are similar but different:

Mailer boxes are designed for only one product delivery in e-commerce. They are giving a branded unboxing experience, ship flat, assemble fast, and are designed to minimize space that is empty. Clothing, cosmetics, minor devices, subscription boxes, and direct-to-consumer orders are among the most common uses.

Shipping boxes are also known as slotted boxes or corrugated boxes, are designed to handle, stack, and protect bulky or heavier products. They are serving as the basis for palletized loads, wholesale distribution, and shipments that require extra cushioning and stress resistance.

Both custom boxes are used by many brands like corrugated shipping boxes for wholesale, restocks, multiple-item shipments, and also customized mailers for orders that are noticeable to customers.

Core Materials and When to Use Them

The selection of material are affecting the cost, sustainability, printability, and protection:

For shipping the goods, a corrugated board is the mainstay. In addition to providing cushioning and stacking strength, corrugated is available in single-, double-, and triple-wall compositions. Types of fluffy materials have an impact on print look, cushioning, and crush resistance. Any product that will be affected by the pallet stacking or transit must be corrugated.

- Paperboard/Folding Carton: Smoother and thinner for better printing and presentation appropriate for a store. Perfect for product packaging, inner boxes, and folding mailers when there is a small risk of transit.

- Kraft: A natural-looking, brown, unbleached paperboard which conveys ecological responsibility. Good for minimalist designs and eco-brands to keep in mind that the print contrast and finish choices are different from those offered by coated surfaces.

- Rigid/Multi-Piece Boxes: Empress Packaging offers expensive chipboard structures used for gift boxes and upscale single-item mailings. Offer better protection, display, yet increase expenses and also space for storage.

Match the material to the desired brand expression, the distribution environment, and the sensitive nature of the product.

Structural Choices: Box Styles and Their Benefits

Select a custom box style due to the package`s transportation, protection requirements, and also custom packaging speed:

Regular Slotted Container (RSC): Reasonably priced and widely used. Useful for both human packaging lines and digital machinery.

The Full Overlap Slotted Container (FOL):It is ideal for objects of greater weights that will require extra vertical support simply because its flaps overlap for increased stacking strength.

Half Slotted Container (HSC): Used for sleeve combinations and displays, this box has a single unlocked side.

Center Special Slotted Container: In order to more evenly distribute stress, the Center Special Slotted Container (CSSC) features flaps that connect in the middle.

Auto-lock and tuck-top Mailers: Simple to construct, ideal for branded experiences and huge online purchase.

Corrugated Mailers: For delicate or expensive items are combining the lasting durability of corrugated packaging boxes with online display.

Design decisions that are affecting packing time as well as protective efficacy include double-wall design, enhanced corners, and flap kinds.

Sizing, Fit, and Dimensional Weight Optimization

A suitable-sized box reduces the chance of damage and shipping the costs:

Take production limitations into account when sizing products with all custom packaging elements (wraps, trays, and inserts).

Reducing the total amount of wasted space in custom boxes by designing them to suit the product closely which is too much empty space raises the dimensional weight (DIM) and the cost of transportation.

To secure products without making the exterior of the custom printed boxes too big, use flexible cushions, nested inserts, or obstacle systems.

Use automated systems or right-sizing methods in shipping to select the ideal custom box for every item and also cut down on shipping air freight.

By delivering the product in perfect condition, a custom box that is the right size reduces logistics and also raises customer satisfaction.

Protection Strategies: Inserts, Cushioning, and Orientation

The layered design is the highly effective way to guarantee the protection:

- Structural Inserts: Die-cut corrugated boxes, divisions, and inserts are reusable while keeping the parts in place.

- Trays Made From Foam or Molded Pulp: Offer specific protection for objects that are fragile and odd shapes.

- Cushioning Materials: Air cushions, fiber pads, paper crumple, and ecological fill offer the protection from vibration and impact.

- Orientation Control: Distribute weight evenly and position delicate parts in order to prevent.

- Insulation and Barrier: For goods that are sensitive to temperature changes, insulated liners or metallic foils are essential.

To lessen the demand for large fillers and the effect on the environment, give passive safety (structure and inserts) the highest priority.

Conclusion

Effective mailers and shipping boxes keep goods, cut expenses, and also improve brand recognition at all point of interaction with customers. Putting emphasis on appropriate substrates, multilayer protection, and right size reduces dimensional-weight expenses and damage while increasing fulfillment reliability. Digital printing allows for modifications without requiring the significant tooling investments, along with strategic printing and also targeted finishes will enhance opening moments in which they matter most. Strong messages about reuse and renewable materials satisfy both regulatory scrutiny and also rising customer expectations. Work with Empress Packaging the right supplier who facilitates quick modifications, test prototypes in real-world settings, and evaluate the returns using customer satisfaction along with damage rates. A logistical need can be turned into a measurable competitive advantage with precise custom printed mailer boxes.

Q1:What differentiates a shipping box from a mailer?

Ans: While shipping boxes (corrugated cartons) are designed for arranging, bulk shipments, and also increased transit protection, custom mailer boxes are most suitable for small product online orders and branded openings.

Q2: When shipping delicate objects what kind of material should I use?

Ans: To stop motion and safeguard delicate products, use corrugated board with the proper wall stiffness (single, double, or triple wall) plus die-cut inserts or molded boxes.

Q3: How might my custom packaging choices lower my shipping costs?

Ans: Utilize single-wall corrugations when safe to cut the material and freight costs, combine SKUs into fewer custom box sizes, and go with custom boxes of the proper size to cut the dimensional weight.

Q4: Are there eco-friendly and recyclable solutions for printed shipping boxes?

Ans: Yes, most paperboard and corrugated boxes may be recycled for more sustainable production, use rigid material structures, board with recycled content, and water-based finishes or low-VOC inks.

Request a Quote

Related Blogs

Published on 23-02-2026 Luxury Rigid Boxes for Premium Product Packaging USA

Published on 20-02-2026 Custom Cardboard Boxes for Secure Packaging in the USA

Published on 17-02-2026 Custom Display Boxes for Retail & Product Packaging USA

Published on 13-02-2026 How to Make a Cardboard Cigarette Box for Custom Packaging

Published on 10-02-2026